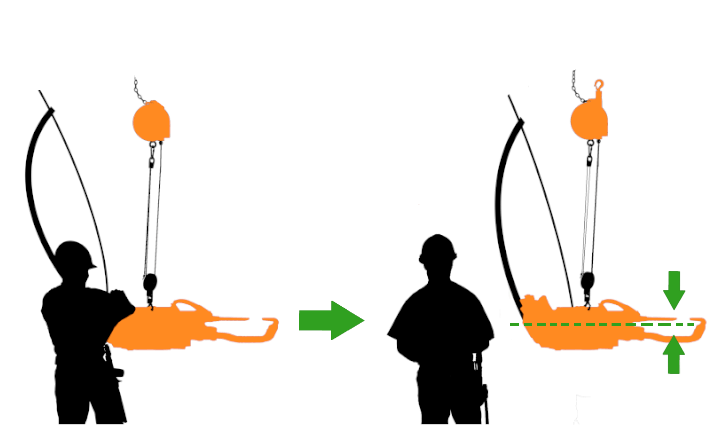

Kromer Balancers, also known Tool Balancers or Spring Balancers, belong to the family of lifting equipment and hoists. They represent manual lifting aids for tools and other loads. In the field, tool balancers are ideally used to position power tools and other assembly aids at the workplace to improve their handling. The improved ergonomics at the workplace shorten throughput times and increase productivity and safety.

Due to the interaction of the suspension spring and the conical cable drum of the tool balancer, the retraction force is nearly the same over the entire cable travel. This makes the load attached to the tool balancer weightless and allows it to be positioned at a desired height. The user can therefore work with less effort and is able to concentrate and work in a precise manner over longer periods of time. In addition, load balancers are also used to organize tools by position them ergonomic and safe at the workplace. As a result, tools are always ready to use and safely stored. However, there are many other useful advantages, that result from our practical handling devices for tools and other loads:

All Kromer Balancers from light to heavy-duty series

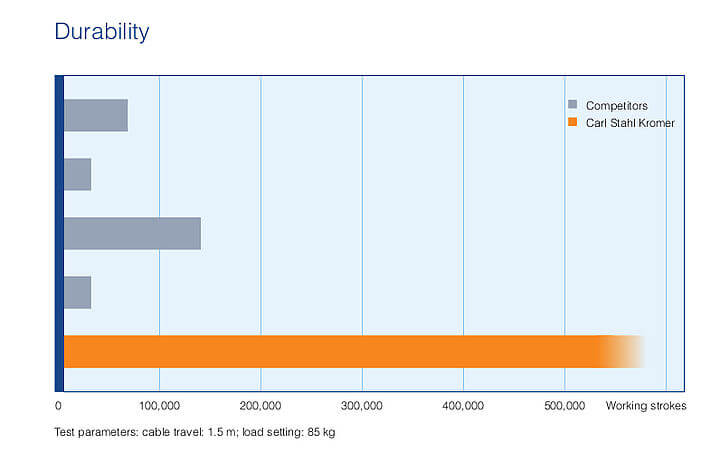

All our Balancers inspire with excellent quality. Thanks to carefully selected materials and more than 100 years of experience in development, design and manufacture, Kromer Tool Balancers are among the most reliable lifting aids for tools and loads up to 300 kg worldwide. A comparative study by the Esslingen University of Applied Sciences certifies, that the Balancers from Kromer are of excellent quality - particularly with regard to the service life. An excerpt from the comparative study shows the performance of a Kromer Balancer with a load capacity of 85 kg compared to other Balancers from other manufacturers in the same category.

Kromer Spring Balancers meet the safety requirements of DIN 15112, have been tested for a long time and comply with the CE guidelines. In addition, they are tested at regular intervals by an external test center and therefore bear the GS certificate for tested safety.

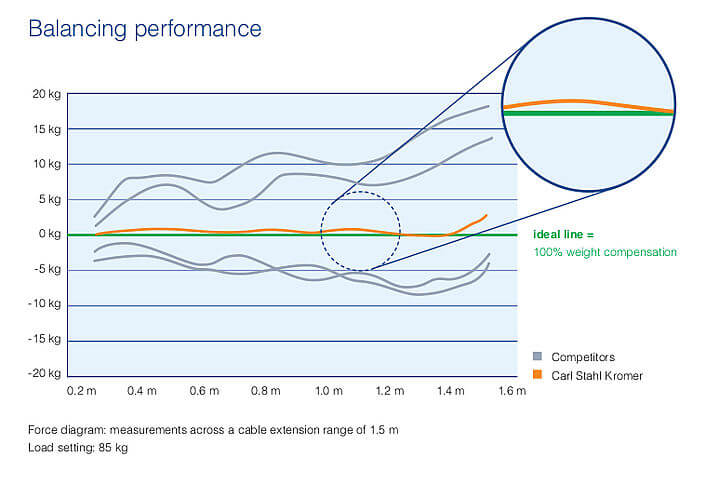

The purpose of a Tool Balancer is to position applications like tools weightlessly at a desired height. As a result, applications can be operated without great effort, which improves the work in production both quantitatively and qualitatively. It is therefore crucial that a Balancer reliably and precisely positions the attached application. Thanks to many years of experience in the production of Spring Balancers and the use of a very high-quality suspension spring, Kromer Balancers are among the most reliable lifting aids in production worldwide.

The figure on the left shows an example of the compensation behavior of a Kromer Balancer with a load capacity of 85 kg over a cable extension of 1.5 m, compared to other Spring Balancer manufacturers. The ideal line (green) shows a 100% compensation behavior. All deviations from the ideal line mean additional effort for the user, since the attached load is not 100% balanced. The user can only carry out his work qualitatively and quantitatively at a high level, if the balancing behavior is very accurate. So the balancing behavior has a direct effect on productivity and thus is a very importation criterion, when choosing a Spring Balancer.