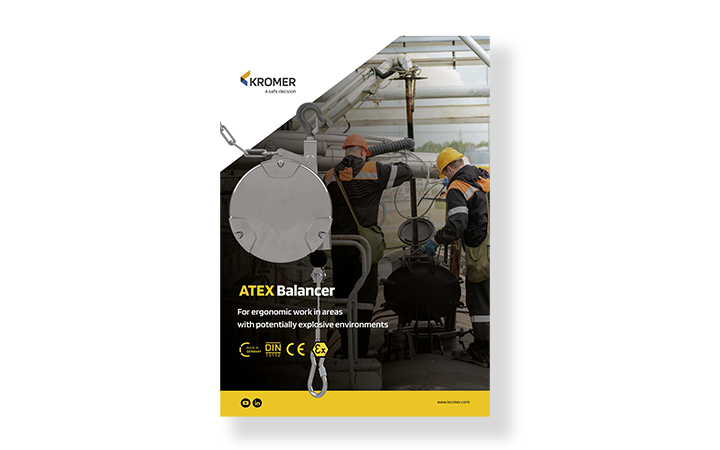

Kromer's ATEX-protected balancers are specifically designed for use in potentially explosive environments. They allow for ergonomic and safe lifting, holding, and positioning of tools or components without generating ignition sources. Thanks to their robust construction and certified materials, they comply with ATEX Directive 2014/34/EU and are suitable for use in Zone 1 and Zone 21.

+ Fatigue-free work even over long periods of time

+ Sensitive and prices work and improved handling of applications

+ Protection of employees from overload

+ Increased safety in the workplace through improved structure and organization

+ Reduced costs by shortening throughput times thanks to ergonomic workplace design I

+ Increase in productivity through improved handling of applications

The legally regulated ATEX marking provides guidance on the correct use of spring balancers in potentially explosive areas though flammable gases and combustible dust. Every device that is used in potentially explosive atmospheres must indicate the areas for which it can be used safely if used as directed. Overview of the suitability / use of KROMER ATEX Balancers:

| Mark | Category | Description |

|---|---|---|

| II: | Group | For use in locations with explosive atmospheres, except in the mining sector. |

| 2G: | Category 2 (Zone 1 Gas) | Use in areas in which an explosive atmosphere consisting of gases, vapors and mists can occasionally occur. |

| Ex h: | Ignition protection category | Protection through constructive safety according to EN ISO 80079-37 (non-electrical devices) |

| llB: | Explosion group | Classification of gases based on their ignitability. The dangerousness of the gases increases from A to C. Covers all gases from B. |

| T6: | Temperature class | Defines ignition ranges based on the ignition temperatures of substances. With> 85 ° C, T6 is the class with the highest requirements. |

| Gb: | Equipment protection level (EPL) | Does not contain any effective ignition sources with regard to gases during normal operation and in the event of expected malfunctions. |

| Mark | Category | Description |

|---|---|---|

| II: | Group | For use in locations with explosive atmospheres, except in the mining sector |

| 2D: | Category 2 (Zone 21 Dust) | Use in areas in which an explosive atmosphere consisting of dust / air mixtures can occasionally occur. |

| Ex h: | Ignition protection category | Protection through constructive safety according to EN ISO 80079-37 |

| llC: | Dust group C | Can also be used with conductive dust. This group “C” includes all other groups. |

| T85°C: | Max. surface temperature | Can be used for dusts and dust deposits with an ignition or smoldering temperature above 85°C. |

| Db: | Equipment protection level (EPL) | In normal operation and in the event of expected malfunctions, it does not contain any effective sources of ignition with regard to dust. |

ATTENTION: Further important information on the correct use of our Kromer ATEX Balancers can be found in our user manual in our download section. In addition, you can also contact our technical support at any time if you have any further questions. We are happy to advise and assist you.

Basically, it takes the following three things for an explosion:

In order to achieve ATEX conformity for the Kromer ATEX Balancers, particular attention was paid to avoiding potential ignition source. All ATEX Balancers have been subjected to an ignition source assessment by external experts from the FSA - the result was positive.

The following technical adjustments have been made to the Kromer ATEX Balancers in order to avoid potential ignition sources:

Zone 0: Constantly or for long periods present – Explosive atmosphere (e.g. gas/air mixture) is present continuously or frequently.

Zone 1: Occasionally present – Explosive atmosphere may occur during normal operation occasionally.

Zone 2: Rarely and briefly present – Explosive atmosphere does not normally occur, and if it does, only for a short time.

Zone 20: Constantly or for long periods present – Explosive dust atmosphere is present continuously or frequently (e.g. inside silos).

Zone 21: Occasionally present – Explosive dust atmosphere may occur during normal operation occasionally.

Zone 22: Rarely and briefly present – Explosive dust atmosphere does not normally occur, and if it does, only briefly.

Zone 0/20: Highest risk → Equipment with very high protection required → Category 1 equipment.

Zone 1/21: Medium risk → Category 2 equipment.

Zone 2/22: Low risk → Category 3 equipment.

The requirements for machines and products vary from industry to industry. Wherever flammable substances such as gases or dusts are manufactured, processed, transported or stored, however, safety plays a particularly important role. Especially in the chemical and petrochemical industry, or in oil and gas production.

The risk of an explosion is based on the probability of the simultaneous occurrence of fuels (concentration of ignitable gases, vapors or dust particles) and oxygen over a certain period of time, which are defined by EX-Zones. KROMER ATEX Balancers are designed for the following ATEX zones:

ATEX protection zone 2 - Explosions though flammable gases:

Area in which an explosive atmosphere consisting of a mixture of air and flammable substances in the form of gas, vapor or mist can be expected during normal operation.

ATEX protection zone 21 – Explosions though combustible dust:

Area in which it is to be expected that an explosive atmosphere in the form of a cloud of combustible dust in air can occasionally occur during normal operation.

Thanks to the explosion-proof design of the Kromer ATEX balancer, it can be used in areas with flammable gases and dusts. Typical industries with potentially explosive areas include the oil, gas, chemical and wood processing industries. In addition, there are many other areas of application in which an ATEX balancer can be used profitably…