ESD-protected Spring Balancers play a crucial role in the electronics industry. ESD stands for electrostatic discharge, a significant risk when working with electronic components. KROMER’s ESD-protected Balancers not only provide ergonomic and precise load balancing but also reliable protection against electrostatic discharges that can damage microchips, transistors, and other sensitive components. By using conductive materials and specialized protective circuits, Kromer ESD Balancers prevent the risk of damage from electrostatic discharges during the assembly process.

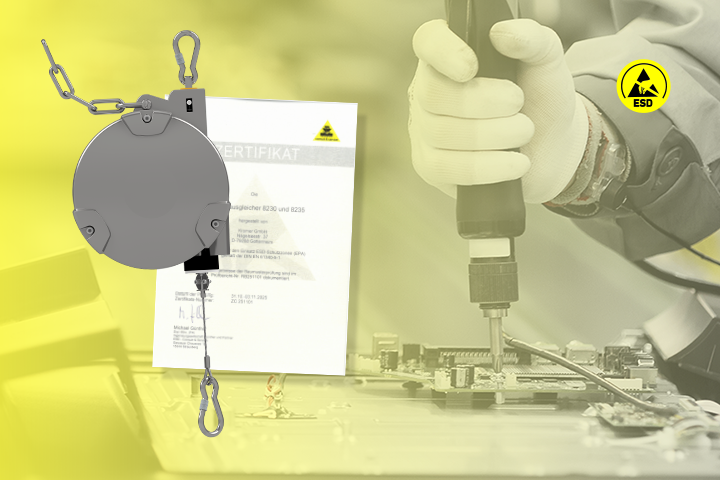

KROMER ESD Balancers are additionally certified by an external testing body and are suitable for use in ESD protected areas (EPA) according to DIN EN 61340-5-1. In environments where electrostatic discharges pose a real threat, ESD-proof Balancers are thus indispensable tools for a smooth, safe, and efficient production

ESD applications become weightless, making them easy and precise to operate. This not only preserves the health of workers in assembly but also has a positive impact on productivity. A well-thought-out and organized positioning of ESD applications in the workplace enhances job safety.

Kromer ESD Balancers have been specifically designed for the production and assembly of electronic components. They are made exclusively from conductive materials and have got an integrated grounding connection to prevent electrostatic discharges. ESD Balancers keep ESD assembly tools and other accessories, such as soldering irons, readily available for the user, ensuring a well-structured, secure, and ergonomic work environment. By neutralizing the weight of assembly tools, the Kromer ESD Balancer enables the user to work with precision and without premature performance degradation.

Understand ESD better

Electrostatic Discharge (ESD) refers to the transfer of electrostatic energy between two objects with different electrical potentials. This can cause damage to electronic components.

ESD can lead to severe damage to electronic components, which, in turn, can result in malfunctions of electronic devices and systems. Avoiding ESD is crucial to ensure the reliability of electronic products.

ESD occurs through the friction of materials, differences in charges between objects, or the movement of electrically charged particles in an electric field. Electrical charges and discharges are ubiquitous. Objects can become charged through friction (for example, walking on a carpet) and discharge upon contact with other objects, leading to electrostatic discharge. A common practical example is touching a doorknob and experiencing a small electric shock.

Electronic components such as semiconductors, integrated circuits, processors, and circuit boards are particularly susceptible to ESD. However, other sensitive devices like hard drives and sensors can also be affected.

ESD can lead to latent damage that may result in failures at a later time. The effects range from temporary malfunctions to permanent damages, often not visible.

By implementing ESD protection measures such as discharge paths, antistatic packaging, grounding facilities, and regular training for personnel, ESD damage can be minimized or avoided.

ESD is generally not dangerous for humans. Typically, the discharge causes only discomfort but does not lead to serious health problems. However, for electronic components and computers, even the smallest electrostatic discharges can cause shorts, damage, and component destruction.

Yes, there are various international standards like the EN 61340 series that establish guidelines for ESD protection in different work areas and industries.

In the event of an ESD occurrence, the affected device or component should be inspected. If uncertainties arise, a professional should be consulted to assess potential damage and take appropriate measures.

ESD is crucial in electronics production, where many sensitive components are processed. Companies implement comprehensive ESD protection programs to ensure the quality and reliability of their products.