By using food grade grease (NSF-compliant) and rust-free materials, Kromer spring balancers (tool balancers and tool retractors) are also suitable for operations in damp working environments with strict hygienic regulations. The tried-and-tested basic principle of Kromer products remains the same: Heavy tools, such as saws for the meat cutting process, are kept ready for the user in a desired position and can therefore be operated precisely and effortless. The increased of ergonomics, significantly improves the workflow in the production process. Like all Kromer spring balancers, our rust-free balancers and retractors are manufactured at our location in Germany and comply with the strict safety standards of DIN 15112.

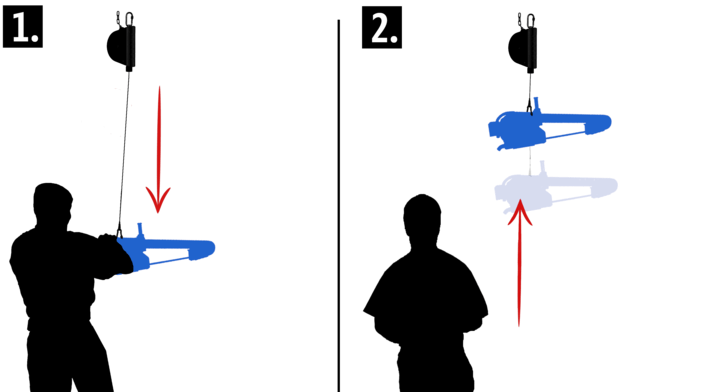

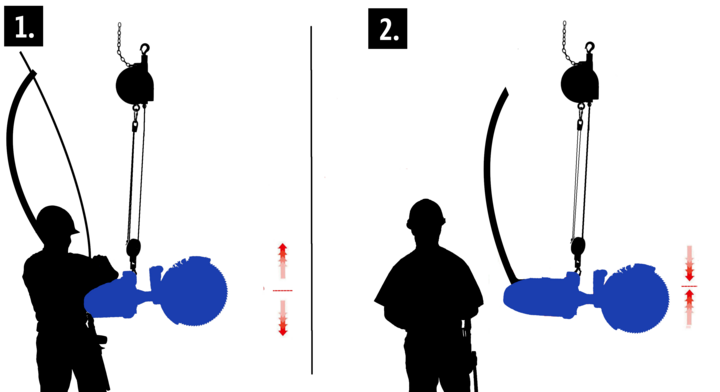

Due to the increasing spring force of the tool retractors, an application is automatically retracted to its inital position, when releasing it. As a result, the workplace remains clean and well organized. Especially when there is limited working space, retractors can be useful aids to be able to use this limited space efficiently.

Due to the constant retraction force of tool balancers, loads such as tools can be positioned at a desired height. The tool balancer neutralizes the load of the attached application, which means that it can be operated without much effort. Thus, balancers are particularly suitable for working steps, that are repeated frequently. The balancer ensures the readiness of applications like power tools or pneumatic tools. Through the weight compensation function of the balancer, users are able to work with less drop in performance, even over a longer period of time.

In order to meet the stringent, individual requirements of the food and meat industry, special attention was paid to the following points when developing our rust-free spring balancer edition:

No varnished/varnished surfaces

Use of food grade fats

Use of abrasion-resistant materials and suitable material pairings

Use of high-quality, rust-free materials

Taking these factors into account, contamination of food through material abrasion is avoided and the functionality of the rust-free retractors and balancers is guaranteed - even in humid working environments. With a load capacity between 0 and 200 kg our rust-free balancer edition can be used in combination with a wide variety of different production aids. The high-quality components of the Kromer spring balancers, protect them against splashing water, steam and regular cleaning with water.

In the demanding environment of the meat processing industry, efficiency and safety are of utmost importance. Rust-free Retractors and Rust-free Balancers prove to be valuable tools, offering a multitude of benefits that enhance operational processes. One of the key advantages of using Spring Balancers in meat processing facilities is their construction from rust-free materials. In environments where moisture is widespread, conventional tools may succumb to corrosion over time, compromising both durability and performance. Kromer Spring Balancers, crafted from rust-resistant materials, not only ensure longevity but also maintain optimal functionality even in challenging working conditions.

Beyond their corrosion resistance, Kromer Balancers exhibit exceptionally high balancing behavior. This feature proves crucial in facilitating ergonomic worksteps by enabling workers to operate machinery and tools with minimal physical effort. The balancing behavior of these devices contributes to a smoother workflow, reduces the strain on workers, and enhances overall efficiency in meat processing tasks.

By counteracting the weight of tools and equipment, Kromer Spring Balancers minimize the risk of accidents caused by heavy loads. This not only protects the well-being of employees but also safeguards the integrity of valuable equipment, reducing the likelihood of injuries and damage in the meat processing environment. The implementation of Spring Balancers (Retractors and Balancers) goes beyond safety; it also results in a tangible increase in productivity. By mitigating the physical strain on workers, these devices empower employees to execute their tasks with greater ease and speed. As a result, the meat processing industry experiences a boost in overall efficiency, leading to enhanced productivity and potentially higher production.

In summary, the introduction of rust-free Spring Balancers in the meat processing industry provides a multifaceted range of benefits. From their rust-free construction for humid environments to their high balancing behavior facilitating ergonomic worksteps, these devices contribute to a safer, more efficient, and ultimately more productive workplace. Investing in Spring Balancers is not just a strategic decision for equipment longevity but also a commitment to the well-being and productivity of the workforce.